Eric Hammang wanted to be the guy in his neighborhood that inspires others to embrace the energy transition. He has an electric home, drives an electric vehicle when he’s not bike commuting, and his logical next step was to install solar panels on his roof. If the energy transition is playing out home by home, why couldn’t he be the first in his neighborhood to make the switch and inspire his neighbors to do the same?

Eric’s journey to power his home with his own affordable, clean electricity is far from ordinary, however: He decided to design and install it himself.

At our Lagers and Legislation social event in May of 2025, Eric casually shared a story about how he’d accomplished this feat. Eschewing professional contractors, he designed his system, ordered solar components, installed 28 solar panels on his steep roof, and even navigated his electric utility’s interconnection process to successfully energize his system.

The result? Eric’s home is now fully electric, powered almost completely by his rooftop solar array, and his annual electric bill — including the electricity he uses to charge his electric vehicle — is under $100.

At Fresh Energy, we love sharing stories about Minnesota’s energy transition — how our communities, businesses, and individuals are taking big steps toward a decarbonized, clean energy future without fossil fuels. Eric’s story offers a unique window into everything that goes into a solar panel installation for your home.

While most people will (and probably should) hire professionals, this post will provide valuable insights into the technical details, challenges, and rewards of a rooftop solar installation. Whether you’re curious about a do-it-yourself (DIY) solar installation or want to better understand the work professional contractors perform, this post goes into all the nitty-gritty details about how Eric successfully installed a DIY rooftop solar system.

Why go solar — and why go DIY?

Eric’s motivation to install solar panels on his roof was straightforward. “I just don’t want to use fossil fuels,” he said. “I want to do everything I can to avoid adding more to my carbon footprint that I already have.” A longtime bike commuter who drives an electric car for longer trips and has recently electrified his home, Eric saw rooftop solar as the next logical step in reducing his environmental impact.

Getting solar on your roof to generate your own affordable, clean electricity is one thing, but installing it yourself is a whole different animal. Eric’s motivation for a DIY approach comes from his enjoyment of tinkering and understanding how things work. “If I’m going to install this solar system, I won’t be able to fix everything myself, but I will have a working knowledge to make simple repairs as needed,” Eric explained. He didn’t just want a solar array; he wanted a system he could understand, fix if necessary, and have pride in having installed it himself.

Plus, Eric would save a lot of money doing the labor himself. Eric’s total out-of-pocket cost was $20,100 before incentives (and only $12,500 after solar energy tax credits, which were recently cancelled in the 2025 federal budget reconciliation bill and will expire on December 31, 2025), significantly less than his quotes of $35,000-40,000 from professional installers.

At a fraction of the cost, Eric expected his solar array to pay for itself much more quickly — as long as he could figure out how to do it himself. Thus began his long, rewarding process to install his own rooftop solar array.

Researching and ordering the rooftop solar components

Eric spent two months planning and ordering his solar components on his nights and weekends, reading about solar systems on the DIY Solar Power Forum. He soon found a reputable online storefront to order his equipment, NC Solar Electric in North Carolina, and connected with its owner Todd Desioto, who had a wealth of experience from his time working on utility-scale solar farms. As Eric emailed Todd questions about his plan and components, the two ended up exchanging more than 60 emails while iterating on plan sets, selecting components, and laying out the system to maximize Eric’s roof space.

Eric’s rooftop solar system design was complex by necessity. He has a steep roof and wanted to place panels on multiple planes of his roof. Solar systems require an inverter to convert the panels’ direct current (DC) electricity into alternating current (AC) that is usable by your home. Between a microinverter, string inverter, or power optimizer, Eric selected a microinverter for his needs, because they work best with the shading patterns that affect solar arrays on multiple roof planes. Specifically, he used a mix of Hoymiles microinverters: some that handle four panels each, others that handle two panels, and traditional one-to-one units.

The standing seam metal roof Eric had installed in 2022 allowed him to use specialized mounting hardware from S5 that clamps onto the roof’s raised seams without any penetrations — great peace of mind from any future roof leaks. This eliminated the need for traditional racking systems and their associated weight, but it also created new, tedious challenges to route cables and place the microinverters correctly.

Selecting the proper components also proved to have a learning curve. Eric discovered that many solar components that are safe for off-grid solar systems don’t have the certifications needed for grid-tied installations (where the solar system connects to the electric grid). With grid-tied systems, electric utilities require components to meet certain safety standards to ensure system integrity and safety. Eric navigated the dropdown menus in Xcel Energy’s interconnection portal before ordering parts so he was confident he would be using Xcel-approved hardware, which occasionally required direct communication with Xcel Energy representatives to confirm his parts would meet their standards.

Once Eric was confident with his system design and the solar equipment was delivered to his door, the next step was even bigger: physically installing the solar panels on his roof.

Installing the roof solar system

Even though it only took several months for Eric to install his solar system in 2023 on nights and weekends, he notes the physical work proved to be more challenging than the planning. His roof’s steep pitch and slippery metal surface offered little traction, meaning he had to set up a harness system to move on the roof properly.

As he began installing the racks and solar panels, Eric realized that while most solar installers start from the roof’s peak and work down, his mounting system required the opposite — building from the bottom up. That sounds simple, but it required him to carefully lift solar panels over the row he’d just installed, making the process more irritating.

In what might be the most impressive feat of his engineering ingenuity, Eric devised a custom pulley system to lift, maneuver, and place the solar panels onto the mounting system one by one, all by himself. At first, Eric prototyped a trolley system using caster wheels (Eric has experience in welding) that could run on the standing seams of his roof. Ultimately, he opted for a simpler wooden sliding system that used a 4-to-1 pulley system to slide panels up wooden planks and position them 3/8 inch above the previously-installed solar panel. This allowed him to lift panels up and over the existing array, then safely position and secure them with properly-torqued fasteners.

Eric slowly lifted each panel, one by one, until his roof became an array of solar panels. But the installation wasn’t finished yet. The next step was to install the microinverters and run cables along the array.

Placing the cables and microinverters proved tricky, because Eric had to create custom jumper wires running from the farthest panels to each 4-to-1 microinverter. To make sure he could access the microinverters in the future for any necessary maintenance, Eric mounted each one underneath the first row of panels instead of scattered throughout the array — a decision that required moving the panels around like a sliding tile puzzle to complete the electrical connections.

Once the panels were secured and connected to the microinverters, there was still one last hurdle before the panels could provide him with carbon-free electricity: He had to navigate Xcel Energy’s interconnection process to properly connect it with the electric grid.

Navigating the electric utility’s interconnection process

If researching electrical components was taxing and installing panels on the rooftop was physically demanding, interconnecting the solar system with the utility power grid proved administratively challenging to say the least.

Since the electric grid is critical to our society’s everyday needs, state law requires that any new connections to the grid — like residential rooftop solar panels — undergo an interconnection process to ensure grid reliability and safety. For Eric, that meant providing information to Xcel Energy to ensure his solar system met their standards.

It took Eric 2.5 months to navigate Xcel Energy’s interconnection process from initial application to approval, with multiple rounds of revisions for formatting issues. Still, Eric is proud to have gone through the process himself, even if it was tedious.

“The interconnection process isn’t daunting, but it’s not a fast process for your first-timer,” explains Eric. “A simple formatting error on my application could set me back one or two weeks, requiring a small fix and re-submission.”

Plan sets required specific formatting, consistent dating and signatures across multiple pages, and detailed drawings showing both overhead panel layouts and ground-level interconnection views. Changes to the application weren’t difficult to make, they just took time to re-submit and wait for Xcel to approve. Still, the process was time-intensive for a person new to interconnecting solar.

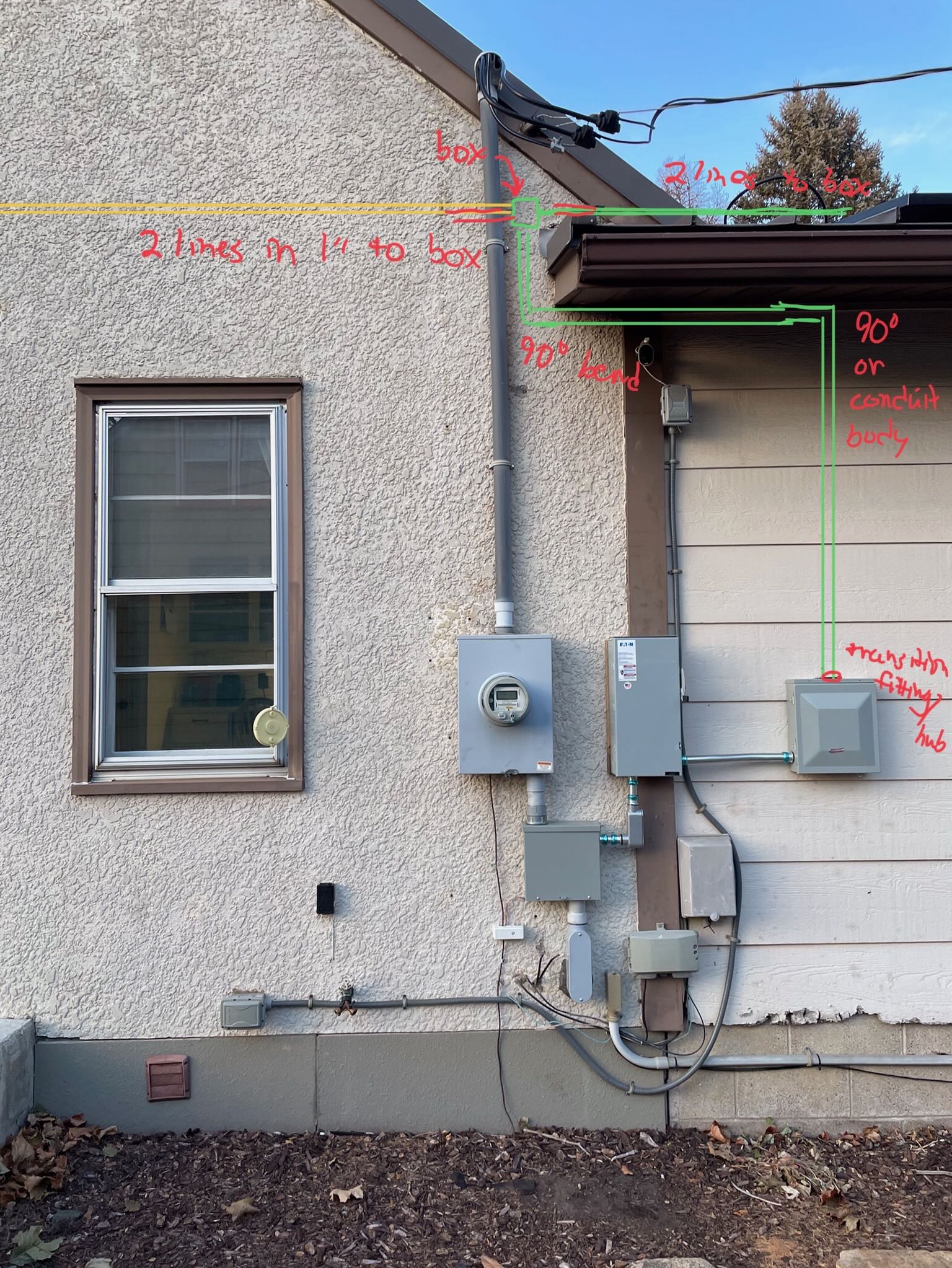

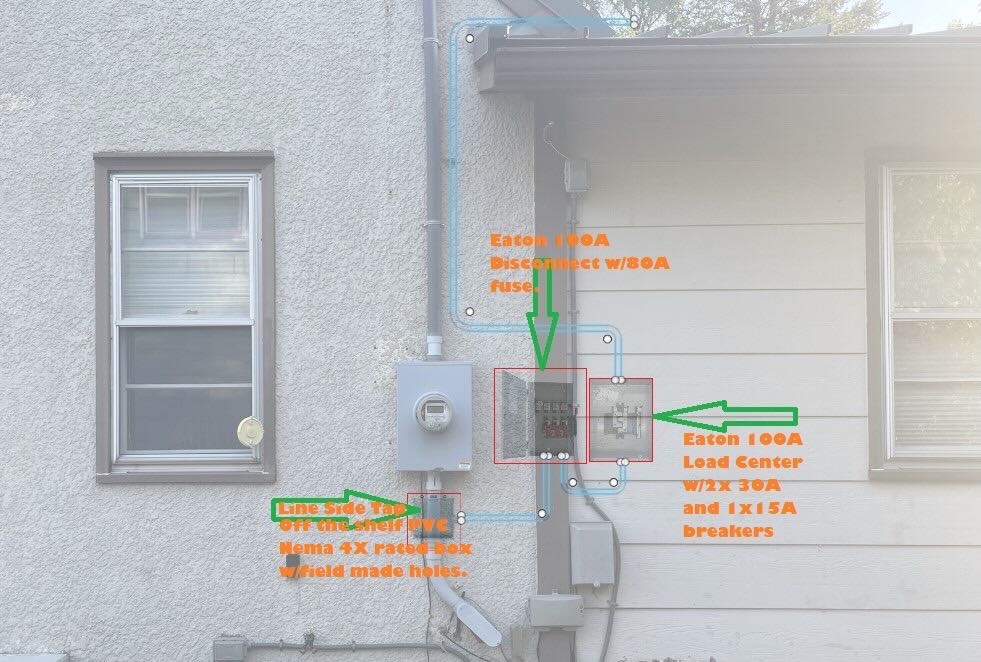

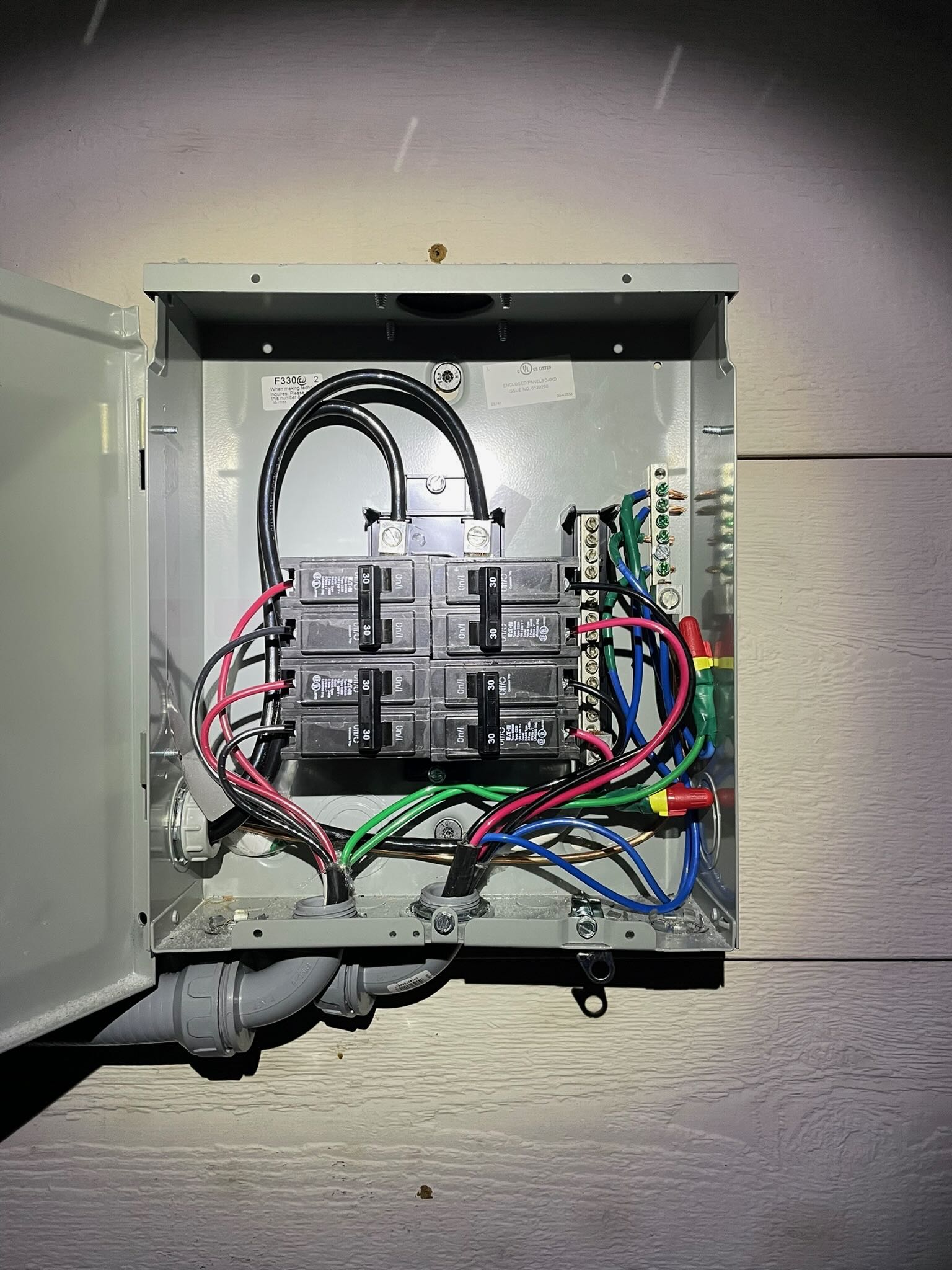

Eric’s solar array size complicated the interconnection process. Solar arrays above a certain threshold can’t connect through standard breaker spaces and require a “line-side tap” — a direct connection at the meter socket that requires a licensed electrician. Finding an electrician willing to take on this relatively small job proved challenging, as it fell below many contractors’ minimum project sizes. Still, Eric found one that was willing to come out and do the quick job at a reasonable price.

Eric also had to navigate complex rate structures. Because he was already on Xcel’s time-of-use plan to charge his electric vehicle during off-peak hours at a cheaper rate, he nearly ended up locked into a rate that would have paid him just 2.5-3 cents per kilowatt-hour for surplus electricity instead of the 15 cents he ultimately secured. That mistake would have dramatically impacted his return on investment.

After a few revisions, Xcel approved Eric’s interconnection application and sent a linesman to Eric’s house to install a net meter and test the system’s rapid shutdown functionality to ensure the system stops producing electricity if the electric grid goes down.

At long last, the climactic switch was pulled, and Eric’s rooftop solar panels began generating carbon-free electricity to power his home, charge his electric vehicle, and feed excess electricity back into the electric grid.

A fully-electric home for under $100 a year

Thanks to his solar array, Eric spent less than $100 on his electric bill in 2024, which includes the electricity he uses to charge his electric vehicle. His system’s performance is impressive: On sunny days, his 28-panel array can generate almost 70 kilowatt-hours of electricity. This May, his system generated enough surplus electricity to create a $126 credit with Xcel Energy, helping to offset his winter heating costs when his panels don’t quite generate enough electricity for his electric heat pump’s power needs and draws from the electric grid for power.

Eric’s home is now fully electric: his rooftop solar provides the majority of the power for his electric heat pump water heater he installed in 2019, the efficient heat pump that heats and cools his home, and he has plans to upgrade to his electric cooktop to induction. He’s even considering additional energy efficiency upgrades like converting his home to a “hot roof” design, where insulation is applied to the underside of the roof deck rather than the attic floor, which should reduce his energy needs even further.

Lessons learned and advice for other homeowners interested in installing rooftop solar

Despite the challenges, Eric would happily design and install his rooftop solar array again if given the chance. “It was blood, sweat, and tears, but I think I’m better off for it,” he said. His experience offers several lessons for other considering adding solar panels to their home, whether installing it themselves or hiring a professional:

Start with the roof. Eric’s decision to install a standing seam metal roof in 2022 was crucial for his solar plans. The new roof provided a solid foundation rated for the additional weight of the solar array, and it eliminated future complications from needing roof repairs under solar panels.

Plan for interconnection complexity. The utility approval process can be the most frustrating part of the solar installation if you’re doing it yourself. Eric recommends budgeting extra time for multiple revision rounds and maintaining detailed documentation throughout the process.

Consider your skills and risk tolerance. Eric’s background in equipment testing, welding, and engineering problem-solving was valuable, but he emphasizes that safety should always come first. His steep roof and complex mounting system created significant risks that many homeowners shouldn’t take on.

Don’t overlook the details. From proper torque specifications on fasteners to understanding electricity rate structure, a successful solar installation requires attention to numerous technical details that can impact safety, performance, and financial returns.

Build relationships with experts. Eric’s collaboration with seasoned solar installers was crucial to his success. Having access to someone you can run ideas with was essential to navigating complex technical decisions and regulatory requirements.

Eric’s story demonstrates both the potential and challenges of a DIY solar installation. While his approach is definitely not one-size-fits-all, his experience shows the true work that goes into a successful solar project.

And as for being the guy in the neighborhood that sparks conversation about the energy transition — well, Eric’s project is working.

A neighbor a few blocks down stopped outside Eric’s house to ask him how he’d done it, and now that neighbor is talking to the same solar vendor Eric collaborated with on his own system. Another asked Eric about his electric appliances, sharing that while he’s retired, he’d started studying HVAC systems at the nearby technical college to help other neighbors install electric heat pumps.

“I definitely have my neighbors thinking about how to switch to clean energy,” Eric said. “That’s a fun benefit of living in a neighborhood and having conversations with your neighbors. Home by home, the energy transition is happening right here in Minnesota.”